Pat Kraft and John Neibergall. Kraft is holding a geodesic sphere — with seven concentric geodesic spheres inside it. “There’s no conventional tool that can make this,” he says. (KCAW photo/Robert Woolsey)

This is not your grandfather’s shop class.

Late last month a group of high school and college shop teachers and a few of their students gathered for a three-day workshop in Sitka’s state-of-the-art Design and Fabrication Lab.

The use of 3D printers and other computer-controlled equipment has revolutionized shop, and turned one of the most remote classrooms in the building into the coolest place in school.

KCAW – Tell me your name, where you’re from, and what you’re doing here.

Neibergall – John Neibergall, Sherwood High School. I’m helping some teachers and students get into digital design and fabrication.

Sherwood High is outside of Portland, Oregon.

Neibergall – You got an idea, you want to make a model or an output of something in three dimensions — whether you build it in wood, metal, plastic, 3D print it. You have to visualize it, and then you get to print it. You have an output of a product in your hand. And that’s what get kids excited.

Read a story about a recent project created by shop students in the Sitka Design and Fabrication Lab.

Yes, digital fabrication gets kids excited. But in this workshop the teachers can barely contain their enthusiasm.

My name is Pat Kraft. I’m one of the instructors at Portland Community College, in Portland. I grew up in an era where Star Trek was, you know — Star Trek was young, I was young, and the thought of having a replicator, where you could put something in there and create something just like it.

And now they have the tools to create just about any kind of machine part. Even parts that are not for machines.

Winship — I’m Kent Winship with Bristol Bay/Dillingham campus, UAF

KCAW — What are you working on right now?

Winship — This is a scan. We’ve got a fetal orca whale that swam up the Freshwater River. Two parents, and one of them was pregnant. So we’ve got the fetus. It’s mostly cartilage. And we’re going to try to scan it, and then print it out in plastic before we lose those cartilage parts.

KCAW – Scan it how?

Winship – A laser scanner than can measure a surface at 20,000 points per square inch. It will record it and put it into a CAD — computer aided drafting program — and we can actually print it out in plastic. And were even talking about trying to mill it out of a CNC mill out of bone or something.

CNC stands for computer numerical control. Besides a pair of 3D printers, this lab has a CNC vinyl cutter, and a laser engraver. What’s got these guys most excited is not necessarily the ability to make a whale fetus, it’s about trying to make that fetus, and failing.

Neibergall and Kraft are pioneering the integration of technology into shop class. They say repetition is education.

Neibergall — Kids are afraid to fail, and this forces them to fail — or fail forward, if you will. If it doesn’t work, you can tweak it…

Kraft — Failure’s okay. Because that’s part of the improvement process.

Neibergall — Because that’s what industry wants: People who aren’t afraid to fail forward. Reinvent. Remodify. And make it right. And it might take four or five iterations. But we can do it quickly.

“I failed…”

Randy Hughey is the recently-retired wood shop teacher at Sitka High. He wrote the grants for Sitka’s Fab Lab and helped a local grant writer, Lily Herwald, develop the proposal for this workshop.

Hughey has microwaved some chocolate chips, with unfortunate results.

“Well, I was just trying to melt chocolate to put into this mold that John has made.”

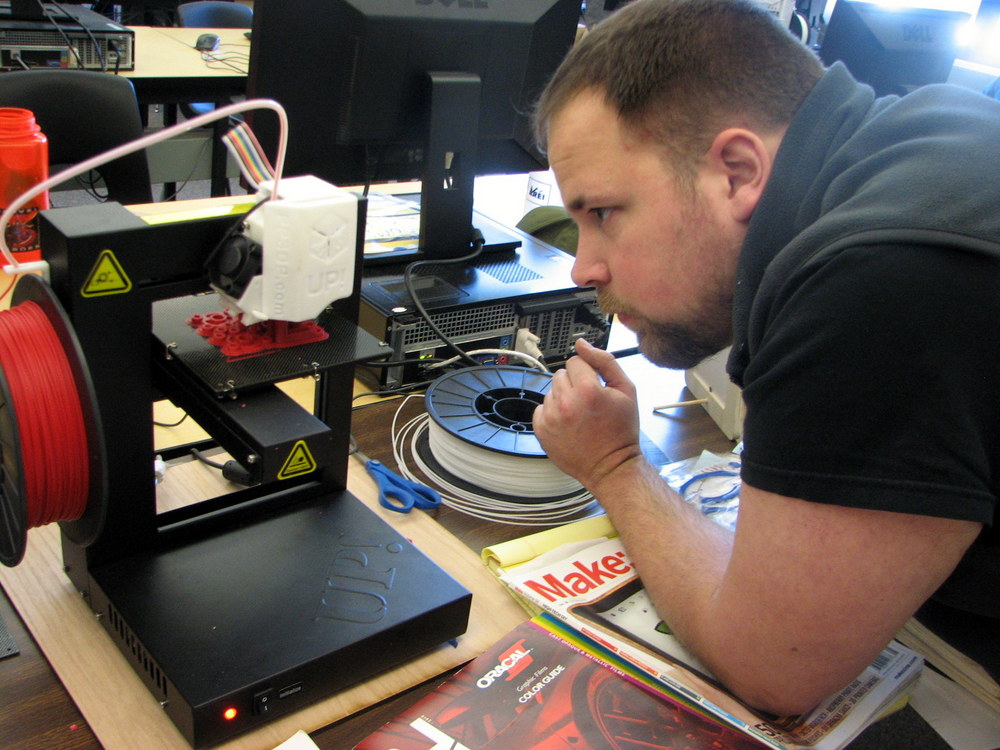

Metlakatla Science teacher Jason Pipkin watches as the printer creates metric screws for a quadcopter his students are building. (KCAW photo/Robert Woolsey)

Digitally fabricated custom candy bar molds. This technology gives kids the ability to aim for the stars, but a prom date is not a bad start.

Neibergall — What my kids did is made prom invitations for the young ladies, wrapped it up in chocolate, and it said Prom? on it.

KCAW — Wow!

For a moment, it sounds like the shop class I remember. But it’s not. John Neibergall assures me that I’m looking at a different sort of future for technical education.

KCAW — Shop used to be the dark space at the end of the hall.

Neibergall — Dumping grounds? That’s the term we tend to say. But now the creative piece that is driving the economic recovery is manufacturing. And if we can get young people excited about that and see the career potential, that’s what’s going to help us get out of our slump, if you will.

KCAW — It comes back to Star Trek, eventually.

Neibergall and Kraft — Right!